A Comprehensive Guide to Careers in Food Packing: Roles, Skills, and Opportunities

Behind every safely delivered meal or grocery shelf is a team working to ensure food items are properly packed and protected. This guide explores how food packing professionals manage tasks like monitoring quality, maintaining hygiene, and handling technology-driven workflows in settings ranging from major manufacturers to independent producers. With growing demand, evolving automation, and options for both full- and part-time roles, the field offers insight into what it takes to succeed and how individuals weigh different opportunities.

The food packaging industry represents an important component in the global food supply chain, contributing to product safety, efficiency, and regulatory compliance. Careers in this field have traditionally offered various positions across different skill levels. This article explores general information about the food packaging sector, including typical roles, skill requirements, and industry characteristics to provide educational context about this field.

Exploring Food Packaging Salary Considerations

Food packaging compensation has historically varied based on several factors including position type, experience level, geographical location, and company size. According to general industry data, entry-level packaging positions have typically ranged between $25,000 and $35,000 annually, while roles involving technical skills or supervisory responsibilities have generally fallen between $40,000 to $60,000. Specialized positions in quality assurance or equipment maintenance have sometimes reached the $65,000 to $85,000 range.

Compensation in this sector has traditionally correlated with experience and certifications. Some companies in this industry have offered shift differentials for non-standard hours. Additionally, larger food manufacturing operations have sometimes provided benefits packages including healthcare and retirement plans, which can affect total compensation beyond base salary figures. These figures represent historical industry patterns rather than current specific openings or guarantees.

Entry Level Food Jobs: Understanding Packaging Basics

The food packaging sector has traditionally included various entry-level positions. General packaging operators, production line workers, and material handlers represent common position categories that have typically required minimal qualifications beyond a high school diploma or equivalent. These roles have generally involved operating basic packaging equipment, inspecting products, and monitoring packaging integrity.

Training for entry-level positions in this industry has typically focused on food safety protocols, equipment operation, and quality control procedures. This educational approach has made food packaging knowledge potentially accessible to those with diverse backgrounds. Some facilities have historically offered structured advancement pathways, allowing workers to develop specialized machine operation skills, quality assurance knowledge, or supervisory capabilities through additional training and experience.

Part Time Warehouse Work in Food Packaging Contexts

The food packaging industry has historically included part-time warehouse positions within its operational structure. These roles have typically involved activities such as receiving shipments, preparing materials, storing products, and organizing inventory. Schedules have often included evening and weekend shifts, reflecting the continuous nature of many food production operations.

Part-time warehouse positions in food packaging facilities have traditionally provided exposure to food safety protocols, inventory management systems, and production environments. Some companies have offered part-time employees proportional benefits including paid time off and retirement plan eligibility. This information reflects general industry practices rather than specific current openings or employment guarantees.

Automated Food Processing: Technical Aspects of Packaging

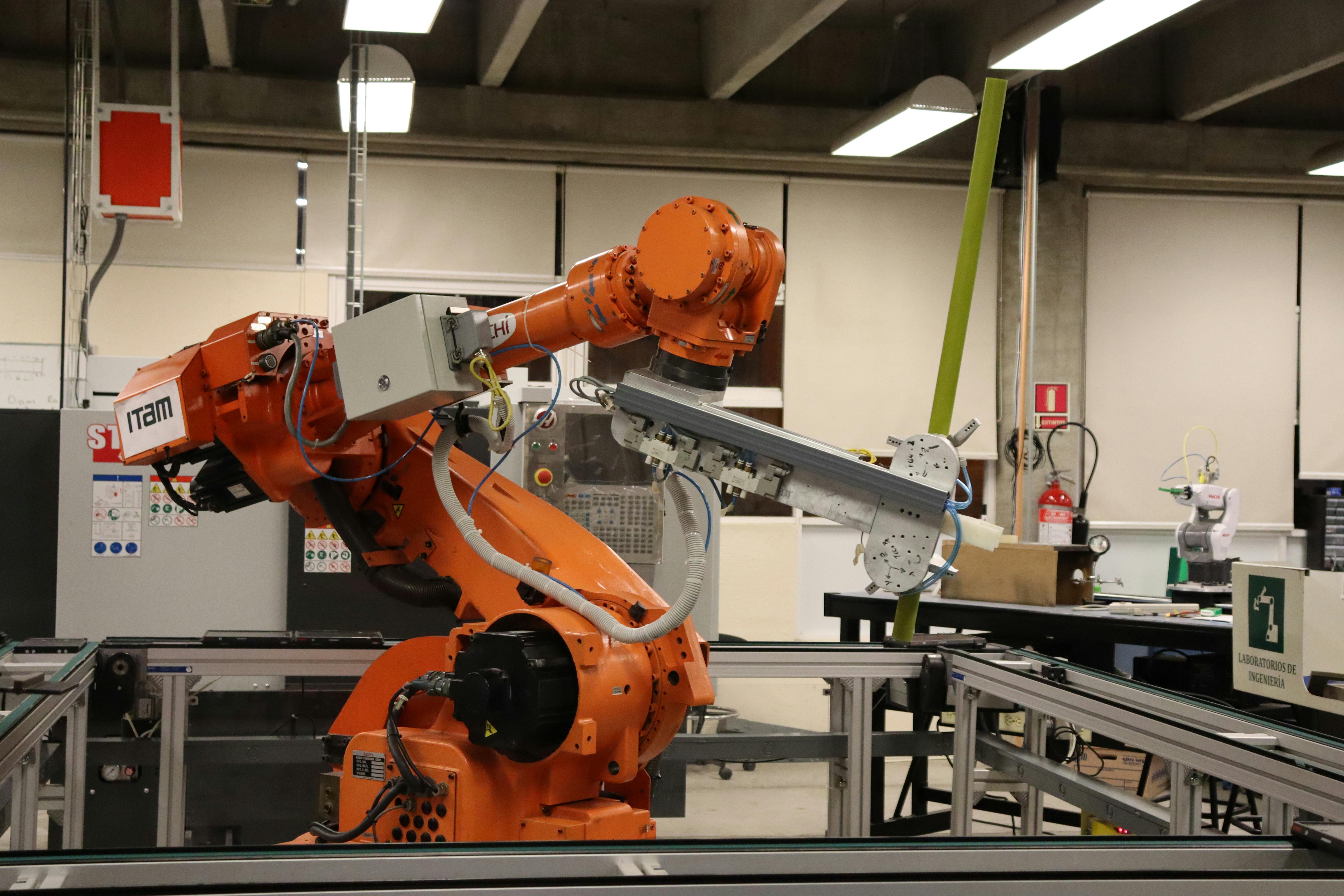

The increasing automation of food packaging operations has created a category of technically-oriented positions involving programming, operating, and maintaining equipment. These roles have typically required specialized training in electronics, mechanics, or computer systems. Technicians working with automated packaging systems have historically earned different wages than general production staff, with compensation varying based on expertise and responsibilities.

Career paths in automated food processing have included PLC programming, maintenance work, and production engineering. These roles have typically required either technical certifications or associate degrees in relevant fields. The growth of automation represents an evolving aspect of food packaging, as companies have invested in technology to improve efficiency and consistency over time.

Skills Development and Career Education Opportunities

Success in food packaging careers has traditionally required a combination of technical competencies and interpersonal skills. Technical requirements have varied by position but often included understanding of food safety principles, mechanical aptitude, and familiarity with quality control procedures. For advancement into more specialized roles, knowledge of process improvement methodologies like Lean or Six Sigma has been valuable in many contexts.

Professional development in food packaging has frequently involved industry-specific certifications such as HACCP (Hazard Analysis Critical Control Points), SQF (Safe Quality Food), or specialized equipment operation credentials. Additionally, associate degrees in food science, manufacturing technology, or supply chain management have been relevant educational pathways in this field, potentially leading to more specialized roles in process management.

Workplace Environment and Industry Characteristics

Food packaging facilities have historically varied in working conditions, from temperature-controlled clean rooms for sensitive products to more traditional warehouse environments. Most positions have involved standing for extended periods, some physical exertion, and adherence to safety and sanitation protocols. Larger facilities have typically operated multiple shifts, while smaller operations have often maintained more traditional business hours.

The food packaging sector has continued to evolve with technological advancements and changing consumer demands. While automation has transformed some traditional roles, it has simultaneously created different position categories for those with technical aptitudes and problem-solving abilities. This information is provided for educational purposes about the industry rather than as an indication of specific job availability or hiring trends.

The food packaging industry represents a sector with diverse position types across various skill levels. This article has provided general information about the field, including typical role categories, common skill requirements, and industry characteristics. This educational overview is intended to offer context about the food packaging sector rather than specific employment opportunities or hiring information.